The various schemes of transformer connection are identified systematically with an alpha-numeric string. Two letters represent the method of connection followed by a number which represents the phase shift of the secondary voltage relative to the primary voltage, expressed in hours, where one hour is equal to an angle of 30 degrees. The first letter is a capital letter, which relates to the higher winding, where Y=star, D=delta and N=neutral lead. The second letter is a small letter, which relates to the lower winding, where y=star, d=delta, z=zigzag and n=neutral lead. So Dy5 specifies a transformer with a delta higher and a star lower, where the lower voltage lags the higher voltage by 150 degrees.

Winding selection for 3-phase transformers

In practice the most commonly used transformer connections are Yy, Dy, Yd, Yz and Dz. In addition the star and zigzag have a neutral point which is either lead-out or latent. Correct connection of a 3-phase transformer depends on several factors:

- Supply system:

- 3 or 4 wire mains network

- from converter

- Transformer Power

- Voltage level

- Load asymmetry

- symmetrical voltage

- asymmetric voltage

- Economic reasons (cost of construction and connection method)

1) Yy system is applied mainly for low power applications for symmetrical 3-phase loads, however its is sometimes used in high power applications where the neutral point must be earthed. This system has the disadvantage that the third (and other zero-sequence) harmonics are not isolated and can cause problems of overvoltage and imbalance especially at low loads. These problems can be reduced by the addition of a compensation winding connected in delta.

2) Dy system is usually applied to step-down transformers with high rated power, connected to a low voltage 3-phase distribution network. If the neutral wire is provided the user has the benefit of both line to line and phase voltages. It has the advantage of reduction of zero-sequence fluxes and associated currents.

3) Yd system is used mainly for step-up applications where the primary side needs to be earthed either directly or via an inductor. This system has the advantage of eliminating zero-sequence currents.

4) Yz and Dz systems are used for step-down applications of low rated power. Phase voltages can be used where the neutral lead is available. This solution is rarely used due to economic reasons. Comparing zigzag to star windings the number of turns required is 2/v3 higher, thus costing about 15% more. So this is limited to supplying asymmetric single phase loads whilst maintaining symmetry on the supply side.

Only the basic properties of the various connection systems have been presented above. For proper operation of the transformer it is important to select correctly. Sometimes it is necessary to make a detailed analysis of the entire system, considering converter type, load asymmetry and supply type, before correct selection can be made.

The most commonly applied connection systems of 3-phase, 2-winding transformers

In order to provide power from a 3 phase supply to a multi-phase load (e.g. 12 pulse rectifiers where 6 phases are used), it is necessary make a power conversion. This can be achieved by employing a transformer with a multi-phase secondary circuit.

There are various schemes possible including double star, double delta and so-called fork winding.

A range of transformers that convert from three phase to multi-phase systems are shown below:

Special systems of transformer connection.

Transformer with non-typical construction and special properties can be created to meet specific technical requirements.

Scott’s system – 3/2 phases:

In Scott’s system, shown below, two single-phase transformers Tb and Td are employed to convert from

a 3-phase supply to two single phase circuits. The advantage of this system is that the single phase circuits have the same current magnitude (with π/2 phase angle between them) and the 3-phase supply is loaded symmetrically.

Vv - connection – 3/1 phases:

The Vv system is the next most widely used method for conversion from a 3-phase supply to a single phase load. Here the transformer iron construction is the same, but with primary and secondary windings only on the two outer legs. Connection is as shown below. This system has the advantage of providing high single phase power to the load, but with the disadvantage of asymmetric loading of the 3-phase source. The centre phase has twice the current of the outer two phases.

Insulation class Identifies the temperature rating of an insulating material used, where a letter code indicates the maximal working temperature of the transformer. Exceeding this temperature during continuous operation would shorten the service life of transformer and the period of its failure-free operation.

| Insulation class symbol | Maximal temperature allowed continuously | Maximal increase of windings temperature for maximal ambient temperature of 40oC as per IEC 61558 |

Maximal increase of windings temperature for maximal ambient temperature of 40oC as per EN 60726 |

| [°C] | [°C] | [°C] | |

| A | 105 | 60 | 60 |

| E | 120 | 75 | 75 |

| B | 130 | 80 | 80 |

| F | 155 | 100 | 100 |

| H | 180 | 125 | 125 |

| C | 220 | --- | 150 |

IP Code (International Protection Rating) as defined in IEC 60529.

This classifies the degree of protection provided by an enclosure against the ingress of solid objects and of water. The code consists of two digits, the first digit relating to solid objects, including body parts and the second relating to water. An additional letter indicates the degree of user protection afforded against direct contact with hazardous parts.

| First digit of code | Description | Second digit of code | Description |

| IP0X | No protection. | IPX0 | No protection. |

| IP1X | Protection against the penetration of objects of diameter Ø=50 mm, e.g. human palm. | IPX1 | Protection against water drops falling vertically. |

| IP2X | Protection against the penetration of objects of diameter Ø=12 mm e.g. palm finger. |

IPX2 | Protection against water drops falling at an angle = 150 from the vertical. |

| IP3X | Protection against the penetration of objects of diameter Ø=2.5 mm. | IPX3 | Protection against water drops falling at an angle = 600 from the vertical (e.g.: rain) |

| IP4X | Protection against the penetration of objects of diameter Ø=1.0 mm. | IPX4 | Protection against water splashing from any direction. |

| IP5X | Protection against the penetration of any objects and settling of dust. | IPX5 | Protection against powerful water jets from any direction. |

| IP6X | Dustproof. | IPX6 | Protection against water waves and powerful jets from any direction. |

| - | - | IPX7 | Protection against destruction due to short-time (up to 30 min.) immersion in water, to the depth H=1 m. |

| - | - | IPX8 | Protection against destruction due to long-time immersion in water, to the depth H>1 m. |

Where the level of protection against electric shock is better than that indicated by the first digit of the IP code, an additional letter may be included. The letter code indicates protection against contact with dangerous voltage as follows:

| Additional letter | Description |

| A | Protection against a direct contact with open palm of diameter Ø < 50 mm |

| B | Protection against contact with finger of diameter Ø <12 mm and length < 80 mm |

| C | Protection against contact with a tool of diameter Ø <2.5 mm and length < 100 mm |

| D | Protection against contact with wire of diameter Ø <1,0 mm and length < 100 mm |

Examples of IP protection degree for equipment manufactured by ELHAND are given below:

IP00 - no special protection of equipment

IP23 - protection against the penetration of objects of diameter Ø=12 mm, e.g. palm finger and against water drops falling at an angle = 600 from the vertical (e.g. rain)

IP44 - protection against the penetration of objects of diameter Ø=1.0 mm and water splashing from all directions

IP54 - protection against the penetration of any objects and dust settling and against water splashing from all directions

Cooling method

The method of cooling is marked with a letter code which indicates the cooling medium and the way it is circulated.

In case of oil-immersed transformers the cooling method is indicated with symbol consisting of four letters and in case of dry-type transformers without enclosure or with a ventilated enclosure this symbol consists of two letters.

- first letter – winding medium,

- second letter – winding motion,

- third letter – external medium,

- fourth letter – external motion.

Cooling method coding is defined in standards EN 60076 and EN60726:

| Cooling medium | A – air G – gas other than air W – water |

| Sposób wprawienia w ruch czynnika chłodzącego |

N - chłodzenie naturalne F - chłodzenie wymuszone przez sztuczne wprawienie w ruch czynnika chłodzącego |

Examples of cooling method designations applied at Elhand are as follows:

- AN - dry-type transformer without enclosure or with ventilated enclosure and with natural air cooling

- ANAN - dry-type transformer in enclosure with natural air cooling inside and outside the enclosure

- WF - dry-type transformer without enclosure or with enclosure, water cooled with forced circulation

Types of operation.

There are the following types of operation:

1. Continuous operation - (S1) Operation with a constant load and for an unlimited period of time or at least until a determined temperature increase is achieved. Figure 1 below shows operating period and temperature rise verses time for continuous operation.

Fig.1 Continuous operation (S1)

Tmax – temperature determined for continuous operation.

Descriptions: Moc – Power, Straty elektryczne – Electric losses, Temperatura - Temperature

2. Short-time operation - (S2) Operation for a determined period of time, starting from cold state, with breaks in operation long enough to cool the transformer down to a temperature close to ambient. Operating time (tp ) is given in minutes (e.g. S2-15 min.). Figure 2 below shows operating duty cycle and temperature rise for short-time operation.

Fig. 2 Short-time operation (S2)

Tmax – highest temperature at short-time operation, tp – time of short-time operation.

Descriptions: Moc – Power, Straty elektryczne – Electric losses, Temperatura - Temperature

3. Discontinuous operation - (S3) Consecutive periods of operation and break with a predetermined duty cycle. Discontinuous operation may be designated for example as S3-20%, where the percentage value indicates the ratio of operation time (tp) to the cycle period (t0), where t0 =tp+ts.

Figure 3 below shows operating duty cycle and temperature rise for discontinuous operation.

Fig. 3 Discontinuous operation (S3)

Tmax – highest temperature at discontinuous operation, tp – time of operation, t0 –period duration,

ts – standstill duration.

Description: Moc – Power, Straty elektryczne – Electric losses, Temperatura - Temperature

Two or more transformers are said to be connected parallel when both primary and secondary sides of each transformer are connected to common buses on the supply and load sides respectively as shown in the figures below.

|

|

| a) | b) |

| Parallel operation of: a) 1-phase, b) 3-phase transformers Description: Odbiornik - Receiver |

|

Parallel operation of transformers is correct when:

- no transformer secondary current flows in the no-load state.

- transformers are loaded proportionally to their rated power.

- the respective currents of individual transformers are in phase with each other

In order to fulfill the above conditions transformers which are to operate in parallel must meet the following requirements:

- Rated voltages, both primary and secondary, should be the same (within ±0,5%).

- Transformers should have the same group of connections with the same hourly shift

- Short-circuit voltages of the transformers should not differ by more than 10%

- The operational power ratio S1/S2 (continuous/short-time) should not be bigger than 1/3 for any transformer.

If any of the above conditions are not fulfilled, equalizing currents will flow in the secondary windings of the transformers, resulting in additional losses. This has an adverse influence on the load distribution which prevents the transformers from operating at their full rated power.

Parallel operation of transformers has many advantages, both operational and economical. For example, where the power demand varies over a wide range, fitting one large transformer may be less economical than fitting multiple transformers which are switched to suit the load. During periods of low power demand the core losses of one large transformer would contribute to high inefficiency.

An additional advantage of parallel operation is the fact that the power of a single transformer intended for parallel operation is lower than the power of a transformer working alone with the same load.

Therefore the power and costs are lower in case when reserve transformer is applied.

Transformers are manufactured in appropriate materials to suit the operational climatic conditions. This information is usually included on the rating plate, in the form of an alpha-numeric symbol, in accordance with EN 60076-11, which describes the climatic class relating to humidity, condensation, contamination and ambient temperature. The classification is as follows:

- E0 – no condensation occurs and pollution is negligible.

- E1 – condensation and limited pollution may occur sporadically.

- E2 – frequent condensation and high pollution may occur

Storage, transportation and usage environments are covered by EN 60721-3:

- 1 to 7 - digits indicating the place of application

- K, B, C, S, M, Z - letters indicating the type of environmental conditions which are taken into account

- 1 to 7 - digits indicating the intensity of factor occurrence, a higher number indicates higher intensity

In accordance with EN 60076-11 standard the conditions in which the transformer is located are divided into two categories:

- climatic classes and environmental classes. This standard applies only to dry-type transformers (including autotransformers) with power from 5 kVA (1-phase) and 15 kVA (3-phase) and highest voltage to 36 kV, in which the rated power of at least one winding is higher than 1 kV.

Climatic classes as per EN 60076-11:

| Environmental class | Description |

| C1 | Transformer can operate at temperature T ≥ -5°C, but it can be transported and stored at ambient temperature T ≥ -25°C |

| C2 | Transformer can operate and it can be transported and stored at ambient temperature T ≥ -25°C |

Environmental classes as per EN 60076-11:

| Environmental class | Description |

| E0 | No condensation occurs on transformer and pollution is negligible. It is usually attainable in clean, dry indoor installations. |

| E1 | Condensation can occur on transformer sporadically (e.g. when transformer power supply is disconnected). Limited pollution is possible. |

| E2 | Frequent condensation and/or high pollution. |

In case of dry-type transformers the environmental conditions are important not only during their operation but also when they are stored prior to installation.

Comparison of designations as per EN 60076-11 and PN-68/H-04650 (not applicable now)

| Version of manufacture as per PN-68/H-04650 |

Climatic class / Environmental class | Comments regarding differences |

| N/3 | C1 / E0 | PN-68/H-04650 standard specified lower minimal temperature (-40°C) and higher average maximal temperature (+40°C). In case of PN-EN 60076-11 standard it is (-25°C) and (+30°C) respectively. |

| W/3 | C2 / E1 | PN-68/H-04650 standard specified lower minimal temperature (-40°C) and higher average maximal temperature (+45°C). In case of EN 60076-11 standard it is (-25°C) and (+30°C) respectively. |

Standards of EN 60721 series classify the environmental conditions in which the products are stored, transported and used. Brief information on classification system defined in this standard is given below.

Identification system used for identification the class for given environmental conditions is very developed and consists of the following marks:

- digit indicating the place of application

- 1 - conditions at the place of storage

- 2- conditions during transport

- 3 - conditions in places protected against the influence of atmospheric conditions

- 4 - conditions in places not protected against the influence of atmospheric conditions

- 5 - conditions in land vehicles

- 6 - conditions in vessel environment

- 7 - conditions during portable and non-stationary using of products

- letter indicating the type of environmental conditions which are taken into account

- K - factors of climatic nature (temperature, humidity, insolation, etc.)

- B - factors of biological character (e.g. attack of animals, termites, etc.)

- C - chemically active factors (various chemical factors)

- S - substances exerting mechanical influence (sand, dust, etc.)

- M - factors of mechanical characters (vibration, shocks)

- Z - factors of special character

- 1 to 7 - digit indicating the intensity with which a given factor occurs. Higher digit indicates higher intensity.

- H (high) or L (low) - H or L letters can be added additionaly after this digit and they indicate the frequency of specific conditions occurrence, e.g. temperature is mostly low and never high

Example of full designation as per EN 60721 and including the occurrence of all environmental conditions in places protected against the influence of atmospheric conditions may have a very developed form, such as: 3K2/3Z1/3Z4/3B1/3C2/3S1/3M4.

In case of products manufactured by our company we try to replace N/3 and W/3 designations used in out-of-date PN-68/H-04650 standard with equivalents indicating the same or maximally close environmental conditions. For that purpose we use mostly the following designations of environmental conditions:

- 3K3 or 3K4 as the equivalent of old N/3 designation; and

- 3K7 or 3K7L as the equivalent of old W/3 designation.

The most commonly used designations of environmental conditions as per EN 60721 are as follows:

| Environmental parameter | Unit of measure |

Class 3K3 |

Class 3K4 |

Class 3K7 |

Class 3K7L |

| Lowest air temperature | °C | +5 | +5 | -40 | -40 |

| Highest air temperature | °C | +40 | +40 | +70 | +70 |

| Lowest relative humidity | % | 5 | 5 | 10 | 10 |

| Highest relative humidity | % | 95 | 95 | 100 | 100 |

| Lowest absolute humidity | g/m3 | 1 | 1 | 0,1 | 0,1 |

| Highest absolute humidity | g/m3 | 29 | 29 | 35 | 35 |

| Temperature variation index | °C/min | 0,5 | 0,5 | 1,0 | 1,0 |

| Lowest air pressure | kPa | 70 | 70 | 70 | 70 |

| Highest air pressure | kPa | 106 | 106 | 106 | 106 |

| Solar radiation | W/m2 | 700 | 700 | 1120 | 1120 |

| Thermal radiation | n/a | 6) | 6) | 6) | 6) |

| Movement of surrounding air | m/s | 1,05) | 1,05) | 1,05) | 1,05) |

| Condensation | n/a | no | yes | yes | yes |

| Precipitation accompanied by wind (rain, snow, hail, etc.) | n/a | no | no | yes | yes |

| Water coming from sources other than rain | n/a | no | no | 6) | 6) |

| Ice formation | n/a | no | no | yes | yes |

| 5) - if applicable then appropriate value may be given in accordance with table 2 (as per EN 60721-3-3) 6) - conditions existing in the location can be determined as per the table 2 (as per EN 60721-3-3) |

|||||

In accordance with EN 60721 standard:

- the conditions determined as 3K3 can occur in ordinary working rooms, e.g. offices, shops, production plants where electronic elements are assembled, warehouses of valuable and susceptible products.

- the conditions determined as 3K4 can occur in some working rooms, e.g. production plants where the processes causing the occurrence of high humidity are conducted, normal storage rooms, garages, cellars.

- the conditions determined as 3K7 and 3K7L can occur at the entrances to buildings, in garages, factory buildings, not guarded stations with equipment, storage rooms for products resistant to frost, etc.

1. Ambient temperature:

If a transformer, choke or power supply is designed for operation at the ambient temperature of 40°C and the actual ambient temperature is higher, then the transformer load should be reduced according to the table below. If the load power is not reduced, then the equipment service life will be shorter or it may result in equipment damage.

| Ambient temperature | 40°C | 45°C | 50°C | 55°C | 60°C |

| Load power reduction coefficient | 1 | 0,95 | 0,91 | 0,87 | 0,84 |

2. Operation altitude above 1,000 m above sea level.

If a transformer, choke or power supply is installed at the altitude H >1000 above sea level, then the load power should be reduced according to the table below:

| Installation altitude (above sea level) | 1000 | 1500 | 2000 | 3000 | 4000 |

| Load power reduction coefficient | 1 | 0,97 | 0,95 | 0,90 | 0,85 |

3. Discontinuous operation (S3).

If a transformer is intended for discontinuous operation (S3), then the relationship between the operational duty cycle and power drawn from the load is given in the following table. Hence a transformer with lower continuous rated power (S1) can be selected for discontinuous operation.

| Discontinuous operation S3 in % | 100 | 80 | 70 | 60 | 50 | 40 | 30 | 20 |

| Load power reduction coefficient k3 | 1 | 0,89 | 0,84 | 0,77 | 0,71 | 0,63 | 0,55 | 0,45 |

Example:

Power drawn by load = 10 kVA

Operating period = 2 minutes

Idle period = 8 minutes

Therefore discontinuous operation S3 = [2/(2+8)]x100% = 20%.

From the table power reduction coefficient k 3 = 0.45,

So the corrected load power : 10 kVA x 0.45 = 4.5 kVA.

In order to supply a receiver with power of 10 kVA, for discontinuous operation S3-20%, we can select a transformer of design power = 4.5 kVA or typical, higher = 5.0 kVA.

4. Power frequency.

A transformer designed for a rated frequency of 50Hz may work at higher frequencies (up to 150-200 Hz). This is because the total core losses are inversely proportional to the power frequency at a constant voltage. However, when the frequency is lowered than rated, the supply voltage should be lowered in order to avoid an increase in core losses and no-load current. This relationship is given in the formula below. Overheating and damage to the transformer may result if this voltage reduction is not observed.

|

| where: fN – rated frequency; fp – operating frequency (lower than rated); UN – rated voltage; Up –voltage obtained with supply frequency fp. |

5. Enclosure.

The transformers produced by Eland Transformatory with IP00 protection are designed to operate without restriction in ventilated IP23 enclosures having dimensions detailed in the ELHAND catalogue or provided the ambient temperature of the transformer is in accordance with that given on the rating plate. Where transformers are installed in non-ventilated IP44 or IP54 enclosures, transformer selection should be made after discussion with the the manufacturer to ascertain power loss and power dissipation requirements.

The most common reason of transformer failure is damage to winding insulation. This can be caused by over-current or over-voltage. Over-current occurs when the transformer is overloaded, such as from a short circuit. This results in overheating of the winding which leads to the total destruction of the insulation in a short time.

Overheating of windings can be caused by electrical phenomena as discussed above or non-electrical phenomena, for example by insufficient air exchange, increase of ambient temperature, decrease of water flow (in case of water-cooled windings), fan failure or soiling of fan protective mesh in the case of air-cooled transformers.

Short-circuits cause, in addition to overheating, the occurrence of a very large electrodynamic force between the windings and their elements.

Example of short-circuit current run

u, i – current and voltage before short-circuit, iknu – non-fixed component of short-circuit current, iku – fixed component of short-circuit current, ik – short-circuit current, iud – surge current

Description: chwila zwarcia – moment of short-circuit

These forces are proportional to the square of the current and are taken into consideration at the design stage of transformer. Average durations of non-fixed short-circuit (time after which non-fixed component of short-circuit fades) amount to 0.02 s to 0.2 s. The value of fixed short-circuit current depends on circuit parameters, including transformer short-circuit voltage. The lower short-circuit voltage of the transformer, the higher value of fixed short-circuit current.

Example: if the transformer short-circuit voltage is 5%, then fixed short-circuit current is 20 times higher than rated current.

In order to reduce the fixed short-circuit current and dynamic short-circuit forces our company applies special constructions of transformer windings.

Protections.

Mostly commonly transformers are protected against overloading and short circuit by applying appropriate fuse elements. Fuse current rating and I2t characteristic are the parameters most important in selection. The value of fuse element rated current on the primary side should close to the rated current of transformer primary winding and equal to the upper value of the closest standard fuse elements. Important transformer parameter deciding on time-current characteristics of fuse element is the starting current.Transformer starting current can reach the value 20÷40 times higher than rated value. The transformers produced by our company are characterized by starting current which is higher by 15÷30 times than the rated current, and we can reduce it even more on customer’s request. For example in the transformers intended for supply of medical rooms it does not exceed 12-fold value of the rated current. Therefore the best solution for transformers is to apply fuse-elements with gTr delay characteristics or gL/gG characteristics (they are more available on the market). In case of low-power transformers miniature fuses of TT or T characteristics may be installed.

Run of starting current for ET1MED-6,3 230V//230V (I1n=28A) transformer produced by ELHAND

It is not recommended to protect the transformers with popular overcurrent switches of S type, although their version with D characteristics (band 10-20xIn) is available, because the transformer starting current may trigger an electromagnetic release when the transformer is switched on.

The best solution for transformer protection is the application of switch with adjustable parameters of time-current characteristics separately for short-circuit and overload modules. In addition to that such switches allow to set the delay, so we can ”put to sleep” its reaction, e.g. during the start-up which lasts usually for first 5-7 half-periods. The disadvantage of such switches is their high price.

Also the protections on secondary side can be applied but they protect more the receiver. In this case the value of fuse-elements rated current cannot exceed the value of rated current on transformer secondary side and the fuse-element time-current characteristics depends on receiver character.

Temperature sensors.

Fuses and switches will protect against overloading, but there are many other factors which may lead to overheating of the transformer. For this reason temperature sensors are installed in the windings, depending on the application and requiremnets of the user.

It is possible to apply the following sensors:

- resistance sensors (Pt type),

- semiconductor sensors (e.g. Posistors PTC),

- miniature bi-metal switches NO – (normally open) or NC – (normally closed).

The sensors are placed inside the winding. In some applications, e.g. mining or medical, it is required to install two types of sensors on one winding.

Example: Pt100 type sensor to constantly monitor the winding temperature and additionally a NO or NC bi-metal switch which signals when a temperature limit is the exceeded.

Monitoring temperature is important from a system operational point of view, as well as for the life of the transformer, since constant overheating by 5ºC will halve the service life of the transformer.

Low-voltage power supply networks can be:

- earthed or

- insulated in relation to earth.

The types of low-voltage supply networks are marked with a string of letters.

First letter indicates the relation between network system and earth:

T – direct connection of one network system neutral point with earth

I - all parts being under voltage are insulated from earth or the network system neutral point is connected to earth through a high impedance

Second letter indicates the relation between the earth and the conductive parts which are not under voltage in normal operating conditions:

N - direct connection of accessible conductive parts with earthed neutral point of network system

Example of TN network system (the neutral conductor (N) can be omitted)

Description: Odbiornik - Receiver

T - direct connection of accessible conductive parts (which are subject to protection) with earth, irrespective of the earthing of network system neutral point with PE conductor

Example of TT network

Description: Odbiornik - Receiver

Example of IT network

Description: Odbiornik - Receiver

Third and fourth letters, indicate the system of neutral and protective conductors:

C - one conductor (PEN) fulfills the function of neutral and protective conductors in the entire network system

Example of TN-C network

Description: Odbiornik - Receiver

S - two separate conductors, connected to each other only in the neutral point of network system, fulfill the function of neutral (N) and protective (PE) conductors in the entire network system

Example of TN-S network

Description: Odbiornik - Receiver

C-S - the function of neutral (N) and protective (PE) conductors is fulfilled by one PEN conductor in one part of the system and by separate (N) and (PE) conductors in the second part of the system

Example of TN-C-S network

Description: Odbiornik - Receiver

Modern medicine is supported by sophisticate electronic appliances used to provided diagnosis, treat illness and save life. Such appliances need to be supplied by an extremely safe and reliable power source.

If traditional method of power supply is applied (earthed neutral system), then the electric energy can be dangerous. Especially sick people, children and neonates are exposed to electric shock. Natural human protective barrier, i.e. epidermis, is interrupted during treatments and operations. The patient can be connected to various instruments which are connected simultaneously, through signal lines, with recording devices. Damage to the insulation of any appliance supplied from traditional network causes the risk of electric shock to the patient and will immediately switch off the damaged appliance and sometimes other appliances which are connected to the patient. It is not allowed.

For this reason medical equipment is by an isolated earth supply IT which is manufactured in accordance with the requirements of IEC 60364-7-710 standard.

The application of IT supply system in medical facilities ensures the safety of patients and medical personnel because an insulation failure is detected but:

- there will be no interruption in operation of the damaged equipment

- other equipment supplied from this network will not be switched off

- patient will not be exposed to the risk of electric shock

Medical appliances are fitted with a detection system which warns the operator of degrading insulation.

IT supply system is applied in medical rooms supplying appliances:

- for life support systems

- for critical treatments where interruption is not allowed

- where there is a particular danger of electric shock

- where atmosphere enriched with oxygen occur or may occur,

- where flammable anesthetics and disinfecting agents are used,

- where earth leakage current should be minimized.

Rooms belonging to this type include:

- operating theaters with preparatory room

- rooms for plastering

- dialysis rooms

- heart catheter rooms

- rooms for endoscopy, especially conducted under general anesthetic

- intensive care units

- neonatal intensive care

- others, e.g. beauty parlous

Proper IT supply system in medical rooms requires:

- energy supply from at least two highly reliable and independent sources

- installation of automatic switching system in accordance with EN 60947-6-1 standard

- application of appliances ensuring safe switching and non-sensitivity to momentary interference occurring in supply lines,

- installation of device for constant monitoring of insulation condition in accordance with the requirements specified in the following standards: IEC 60364-7-710; IEC 61557-8; EN 61557-8:2002 U,

- installation of devices for constant control and signalling of medical transformer temperature and load

- making appropriate system of protective earthing and equalizer connections.

Elhand Transformatory from z Lubliniec and Horus Energia from Warsaw offer complete equipment sets, manufactured in accordance with IEC 60364-7-710, for the safe and reliable supply of medical facilities.

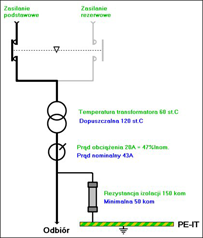

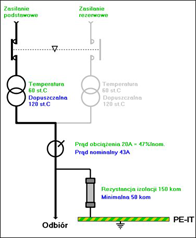

State of nominal operation (no alarm state) of IT supply systems are presented schematically on the figures below:

|

|

|

| HE-111 | HE-112 | HE-113 |

|

Description: Zasilanie podstawowe – Basic power supply, Zasilanie rezerwowe – Reserve power supply, Temperatura transformatora – Transformer temperature, dopuszczalna – allowed, Prąd obciążenia – Load current, Prąd nominalny – Nominal current, Rezystancja izolacji – Insulation resistance, minimalna – minimal, Odbiór – Receiver |

|

|

|

|

HE 101 power supply module |

|